Fabric Belt Scanning

About Fabric Belt Scanning

This permits the operator to plan appropriate maintenance down-time.

Additionally, correlation of time / thickness information with belt ageing, aids in the prediction of likely useful belt life. Knowledge gained through regular condition monitoring also provides valuable assistance in establishing the design parameters for any replacement belting.

The system relies on comparison of belt signatures over a period of time, it is important to have base signature data recorded as soon as possible after belt manufacture or installation. Even if the belt has been in action for a while, an initial signature will capture a baseline scan for CBM technicians to compare / interpret against subsequent data.

Reports

As with our other services, CBM provide and in depth report based which opens with a summary of findings and a list of recommendations in order of priority, to assist effective maintenance planning.

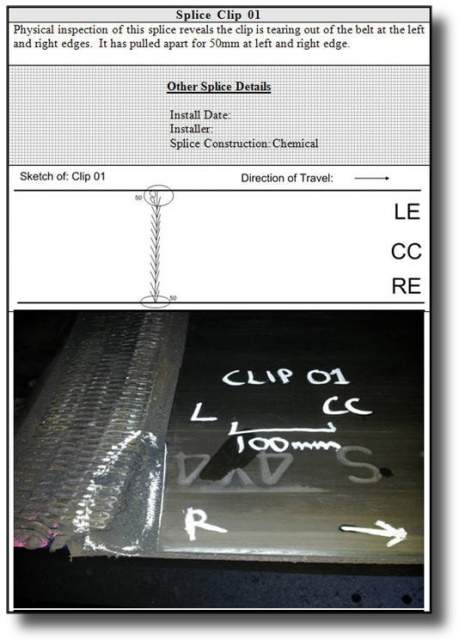

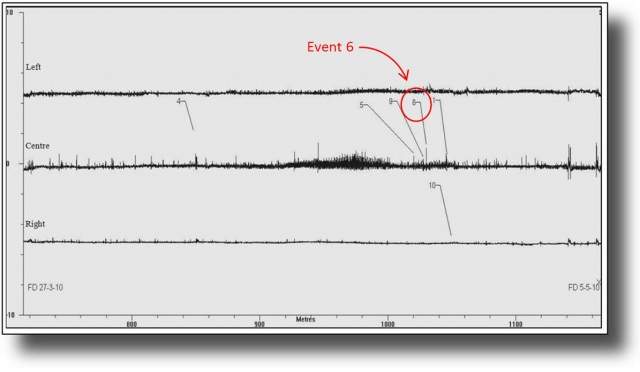

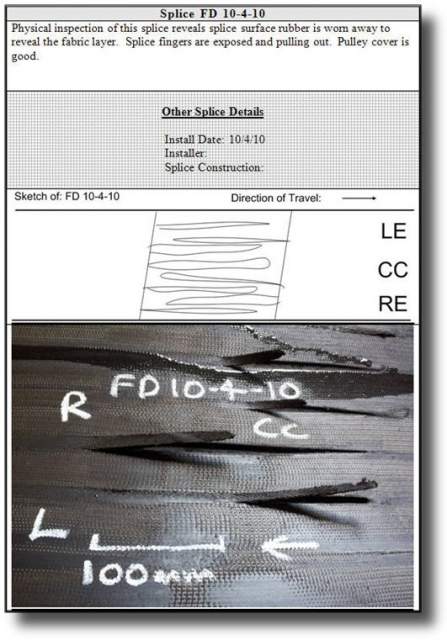

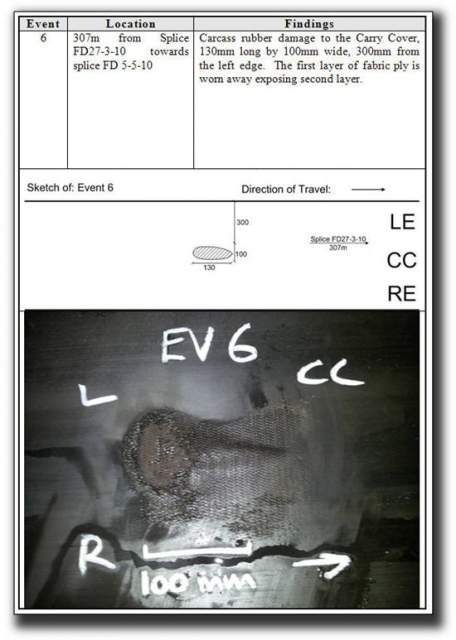

Following are some sample pages - below left is our findings from the inspection of an event, Event 6. The event's location and type of damage are described and there is both a sketch and a photograph for further reference.

Below is the belt signature for the corresponding event. During scanning the belt is divided into three segments across its width: left, centre and right. The left and right sides of the belt are identified by facing with the direction of product travel.

Splices are also monitored. Below are some examples of evaluation of a splice and a clip join. A single splice signature will not indicate what the state of adhesion is, within the splice. Only changes in signature, with time, will give advance warning of impending splice failure. For this reason, regular visual inspection is still the best method for avoiding catastrophic splice failure. This applies equally well for mechanical fasteners.