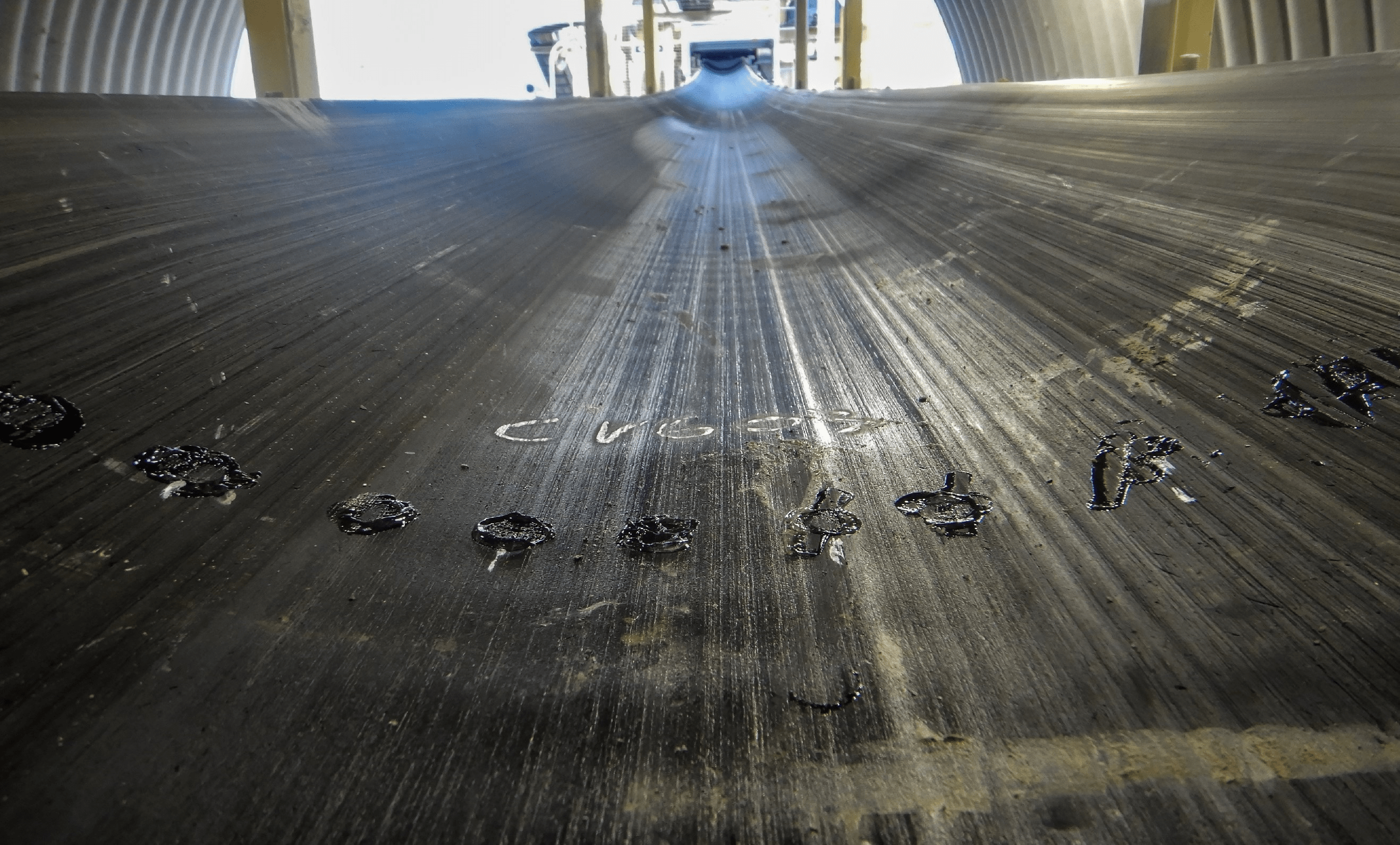

Thickness Testing

About Thickness Testing

CBM utilise proprietary technology to determine the thickness of both covers at predetermined locations. Each static thickness analysis gives a clear indication over time of the belts wear profile which allows two main benefits.

- Firstly, knowledge of wear patterns help to determine such problems as dropped skirts, tracking issues, product build up beneath the return path (causing excessive wear) or load point impacting.

- Secondly, forecasting end of belt life enables multiple repair options such as turning over of belts or realigning of load chutes.

These two benefits help to extend the safe working life of the conveyor belt. Cover thickness measurements can be obtained from steel cord, fabric and solid woven belts.

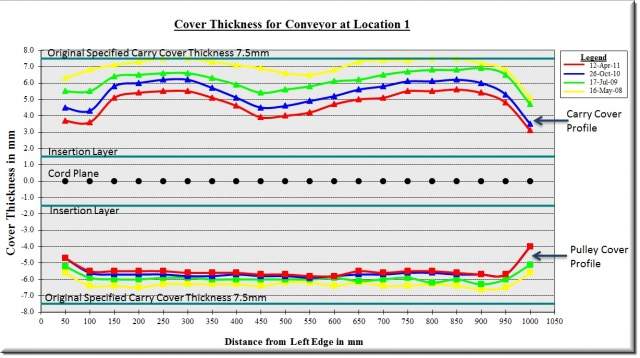

The thickness of both the carry and pulley covers are measured and graphed at predetermined locations along the belt. This gives a cross sectional view of the belt and the wear profile at that specific location.

Based on these static thickness measurements, CBM create a service life prediction for the belting at its current rate of wear.

Elastomer hardness measurements are performed at the same locations as the cover thickness.

These locations are marked, allowing subsequent measurements to monitor the advancement of hardness in the belt covers, with age.

Clear, concise, easy to read and above all, rapid indicators regarding conveyor belt safety and durability.

Provision of the most comprehensive condition monitoring of conveyor belts and systems in the world today.

This system, as with all CBM systems is suitable for both above and below ground applications.

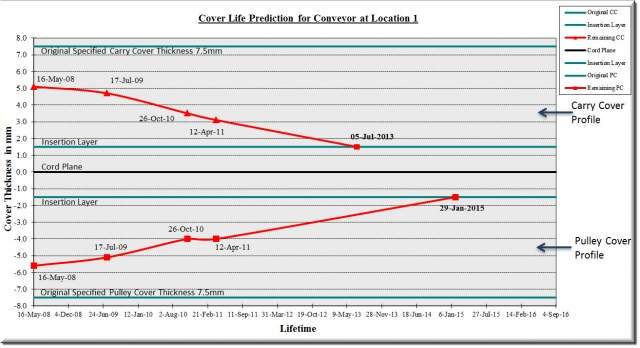

Cover Thickness Graph

Each static thickness analysis gives a clear indication of a belt's wear profile. This helps identify problems such as dropped skirts, tracking issues, product build up beneath the return path and load point impacting.

Life Prediction Graph

CBM can derive a Cover Life Prediction Curve which is based on cover thickness measurements taken across the belting at a selected location. The curve is a trend of cover wear applicable to the location being measured and not necessarily to the whole belt length.

Frequent cover thickness measurements enable accurate life prediction. CBM recommends quarterly measurements for best results.